- Home

- Over ons

-

Engineering

-

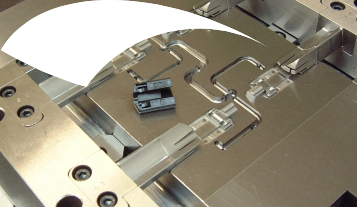

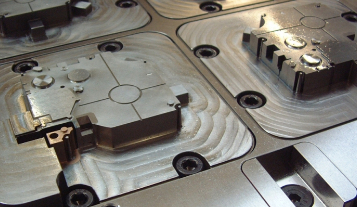

Injection molds for plastics.

Injection molds for plastics.

-

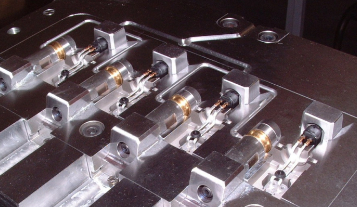

Other types of molds

Other types of molds

-

Design, calculation, and fabrication of dynamically optimal cams and cam mechanisms.

Design, calculation, and fabrication of dynamically optimal cams and cam mechanisms.

-

3D Scanning & Reverse Engineering

3D Scanning & Reverse Engineering

-

Miniature milling

Miniature milling

-

Custom-made feed worms and Archimedes screws.

Custom-made feed worms and Archimedes screws.

-

3D and multi-axis machining, precise (thin-walled) housings machined.

3D and multi-axis machining, precise (thin-walled) housings machined.

-

Medical instruments and implants.

Medical instruments and implants.

-

- Fabricatie

- Kwaliteitscontrole

- Team

- Testimonials

- Vacatures

- Blog

Since its inception in 1970, Stewal has specialized in the design, manufacturing, and repair of injection molds for plastic products.

Both in our design office and workshop (thanks to experienced toolmakers and all the necessary technologies such as electro-erosion, grinding, laser welding, CADCAM, 5-axis and hard milling, etc.), we are equipped to meet the high demands of high-end market segments such as automotive, pharmaceuticals, medical, consumer electronics, and more. We produce small to medium-sized molds, prototype, and multicavity molds, with or without hot runners.

Additionally, we have two injection molding machines (60 tons and 200 tons) for prototyping our molds and producing small series.

In addition to the world of injection molds for plastics, over the years, we have also developed expertise in press and casting molds, blow and vacuum molds, extrusion molds, and die cutting molds.